Útmutató a laposhegyű fúrószárak használatához

Related products Link:

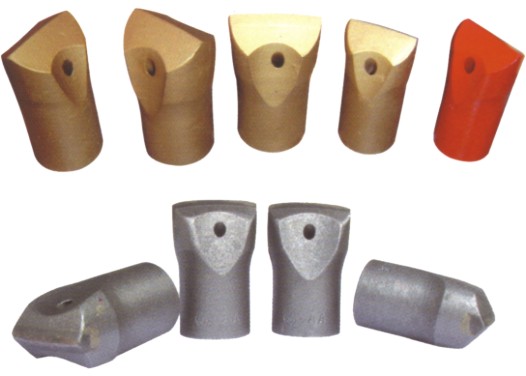

The integral drill is a widely used rock drill bit in China. Its connection form is mainly a conical connection, and it is used in conjunction with a conical drill rod (commonly known as a finished drill). In order to use the inline drill bit correctly and ensure the normal service life, the following points must be paid attention to:

1. Ensure a good fit with the tapered drill rod (the taper is the same, the depth of the drill rod inserted into the drill bit cone hole must be greater than 25mm, and the head of the drill rod should not fill the bottom of the drill bit hole), otherwise the drill bit will easily be lost;

Note: It is best to use the same manufacturer of the drill bit and the tapered drill rod to ensure that the taper is consistent and has a good fit.

2. When drilling holes, the rock drill should reduce the air volume to reduce the damage to the drill bit caused by the high stress of the cemented carbide piece. When the drill bit is completely drilled into the rock, use the normal air volume;

3. When the cutting edge of the drill bit has a platform width ≥ 3mm, it should be replaced or reground in time to avoid reducing the rock drilling speed, causing bit fragments, lobes, and reducing the service life; when the bit has an inverted cone, it should be replaced or reground in time. Grind the drill bit, otherwise it will severely wear the drill bit, reduce the rock drilling speed, or even stick the drill;

4. If foreign objects such as steel bars are encountered when using the drill bit, the drilling position should be adjusted to prevent the drill bit from being damaged;

5. When rock drilling is prone to sticking, the in-line bit should be replaced with a cross bit or a button bit;

6. For the rock that causes serious wear of the straight drill bit, slow rock drilling, and serious fragmentation, you should consider replacing other alloy drill bits or using cross-shaped drill bits or button bits, and notify our company in writing in time to facilitate Deal with it in time. The notification content mainly includes:

1) The model, wind pressure and air volume of the rock drill used;

2) Rock type and hardness, construction location (open air, underground, other), drilling construction method (downward, horizontal, mixed, other);

3) The type, quantity, life, and form of damage to the drill bit;

4), the average life span of normal drill bits;

5) Plan the service life;

6) The average service life of other manufacturers.

7), our company's product model.

7. When the rock is soft and easy to drill, the overall drill (the drill bit is made directly on the drill rod) can greatly increase the drilling speed;

8. For vertical rock drilling, the use of the integral drill can avoid the loss of the drill bit, and at the same time, the normal powder discharge must be ensured, otherwise, the drill bit will be severely worn;

9. During the rock drilling process, the drill bit should ensure the water supply as much as possible to prevent the drill bit from sticking and improve the service life of the drill bit and the drilling efficiency;

10. The company can provide integral drills of the same specifications, different brands and models of alloy sheets.